how do electric trailer disc brakes work

Electric trailer brakes require a brake controller. Youll save about half if you can do this relatively simple job yourself.

Trailer Brakes The Definitive Guide Diamond C Trailers

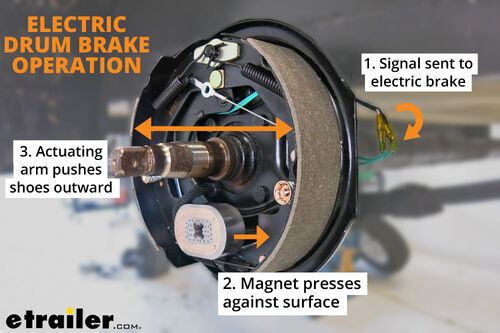

Electric trailer brakes on the other hand work by activating electromagnetic brake drums to create attrition and therefore slow the trailer down.

. The front side with the hitch is separate and slides on the ledge to the back half of the neck. In addition to superior braking disc brake pads are also much easier to replace. They are automatically applied by the brake controller and can be manually operated by a manual control which is installed within reach of the driver.

Electric trailer braking systems provide fast response times and good control over the action of your trailer brakes but they dont stop as hard as hydraulic brakes. The trailer has its own hydraulic disc brake actuator mounted inside the gooseneck or tongue. They then use electromagnets to activate the braking system via the drums.

Instead of repairing them I decided to upgrade to disc brakes that dont need adjusting. The only downside is the cost. Trailer brakes are always using one of the three systems.

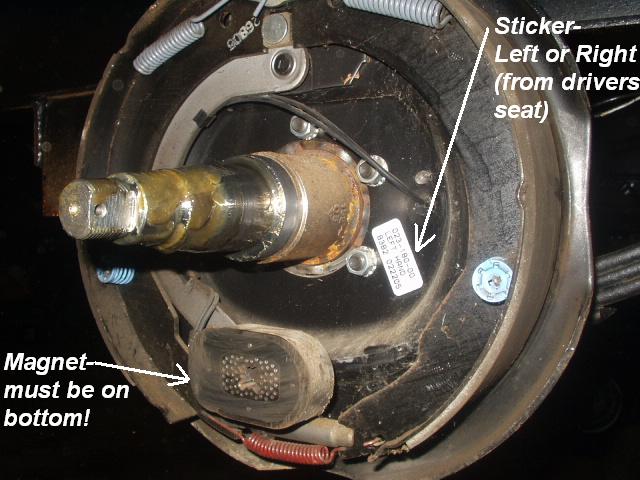

As you already know electric brakes have a magnet which is usually on the backing plate. Last winter we converted our 27-foot Arctic Fox fifth wheels brakes and put them to the test. This actuator converts the electrical signal from your brake controller into hydraulic pressure to press the brake pads against the rotors in turn stopping the trailer.

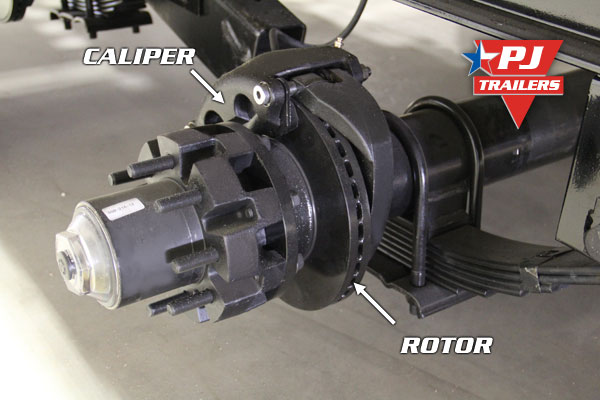

The piston extends and pushes the backing plate of the inner brake pad which then squeezes the rotor. Electric brakes are more simple than surge brakes but they require a brake controller in the cabin of the tow vehicle. And the high pressure lines are installed between the brake actuator and the disc brakes on every wheel.

Unlike hydraulic trailer brakes that rely upon compression of a master cylinder to generate hydraulic pressure to engage the brakes electric brakes supply electrical current to electromagnets inside each drum which engage the brake shoes against the drum lining when the tow vehicles brakes are applied. How Electric Trailer Brakes Work. So when electric power is on it activates the magnet which is then attracted to.

The brake actuator is wired into the 7 pin connector on the trailer where the truck plugs into it. Trailer brakes according to Dave do not require a great deal of maintenance to function properlyAfter driving long distances or through challenging terrain you should examine brake pad thickness and wear patterns at least once a year and look for brake dust around the rim after stopping abruptlyIf you hear the sound of metal on metal. The tow vehicle does not need anything other than an electric brake controller to use this hydraulic brake system.

Electric trailer brakes use a brake controller which is situated in the tow vehicle. Disc brakes are known for providing more consistent stopping and more stopping power in general than drum brakes. We at Performance Trailer Braking specialize in electric over hydraulic systems or EOH.

10-inch Electric brakes are suitable for any axle up to 50mm in diameter. Once the backing plate is attached to the weld rings the drum is then fitted and tightened with the axle nut. This connection is made with a trailer harness that will be connected to the tow vehicle.

How Do My Trailer Brakes Work. We had to completely redo the magnets and the wiring after losin. The electricity to the brakes is controlled via the brake controller and brake light circuit.

How do Electric Trailer Brakes Work. Hydraulic Surge electric and electric over hydraulic. The neck of a trailer is two pieces.

While surge brakes operate independently electric trailer brakes need to be connected to the power of the tow vehicle and be regulated by a brake control unit or electric brake controller. The brake controller is wired into the truck. How Surge Brakes Work.

To a lot of people the idea of using anything with the word electric in the water is a non-starter. The controller is connected to the vehicle battery and the stop light switch. The plate is usually bolted to a flange on the trailer axle which is the passage of the hub and the bearings.

The driver steps on the brake pedal. But electric over hydraulic brakes on boat trailers are now an option on models built by EZ Loader Magic Tilt Pacific Trailers and Loadmaster to name just a few. This device modulates the electric current sent to the electric trailer brake when you press the brake pedal in your car.

This is controlled by a module that is located in the tow vehicle and is applied as you are pressing on the vehicles brake. They require the use of a brake controller that mounts inside your cab so that you can conveniently adjust the action of your brakes - how quickly they apply and how hard they stop depending on trailer. 10-inch Electric braking systems use a four-hole weld ring to secure the 10-inch electric-backing plate to the axle.

Before you shop for new brakes check to see if you have a four- or five-hole trailer axle brake mounting flange. Electronic brakes are most commonly used on caravans and trailers over 750kg and are legally required on all caravans and trailers where the GTM is more than 2000kg. Hydraulic Surge trailer brakes use a surge actuator that releases fluid into the brake as you press down on the brake.

How Electric Trailer Brakes WorkIn this video we describe how Electric Trailer brakes work. Electric brakes work very well when adjusted properly and you can also reach over with your hand and use the brake controller to apply a small amount of braking force if the trailer begins swaying. Electric brakes are constructed with electronic components and a set of magnets that apply pressure to a wheel hub.

Im not a mechanic but heres a very general explanation of how an electric over hydraulic brake system works. This magnet has two conductor wires that are directly connected to the trailer spring. A master cylinder for the trailer brake is mounted on the back half of the neck and has a rod extending to the front half.

An electric over hydraulic trailer disc brake conversion is about 3000 if you hire a mechanic for installation. When a trailer is designed to carry 3000 pounds it must have a working braking system. An electric signal gets delivered to the trailers brake actuator.

The actuator delivers hydraulic fluid pressure to. Like a purely hydraulic system an electric over hydraulic EOH braking system is activated whenever the tow vehicle brakes are. The friction created by the brake pads squeezing the rotor slows down the trailer.

Upgrade Your Trailer To Disc Brakes Boating World

Why You Should Upgrade Your Trailer To Surge Brakes To Electric Brakes

Parts Needed To Add Electric Over Hydraulic Disc Brakes To A Trailer Etrailer Com

Parts Needed To Add Electric Over Hydraulic Disc Brakes To A Trailer Etrailer Com

Hydraulic Disc Trailer Brakes Pj Trailers

Upgrade Your Trailer To Disc Brakes Boating World

Trailer Disc Brake Conversion Electric Over Hydraulic Disc Brakes

Titan Hydraulic Over Electric Trailer Disc Brake Conversion Review And Installation Tips And Photos Drum Brake Hydraulic Trailer

Trailer Drum Brakes Vs Disc Brakes Making The Decision Etrailer Com

Installing Electric Brakes On Your Trailer R And P Carriages New Used Trailer Sales Rental Near Chicago

Upgrade Your Trailer To Disc Brakes Boating World

Titan Hydraulic Over Electric Trailer Disc Brake Conversion Review And Installation Tips

Trailer Disc Brake Conversion Electric Over Hydraulic Disc Brakes

Trailer Drum Brakes Vs Disc Brakes Making The Decision Etrailer Com

Trailer Brake Kits Trailer Brake Installation Trailer Disc Brakes Performance Trailer Braking

Trailer Disc Brake Conversion Electric Over Hydraulic Disc Brakes

Trailer Drum Brakes Vs Disc Brakes Making The Decision Etrailer Com